Resiliently | Powerful

Change. And win.

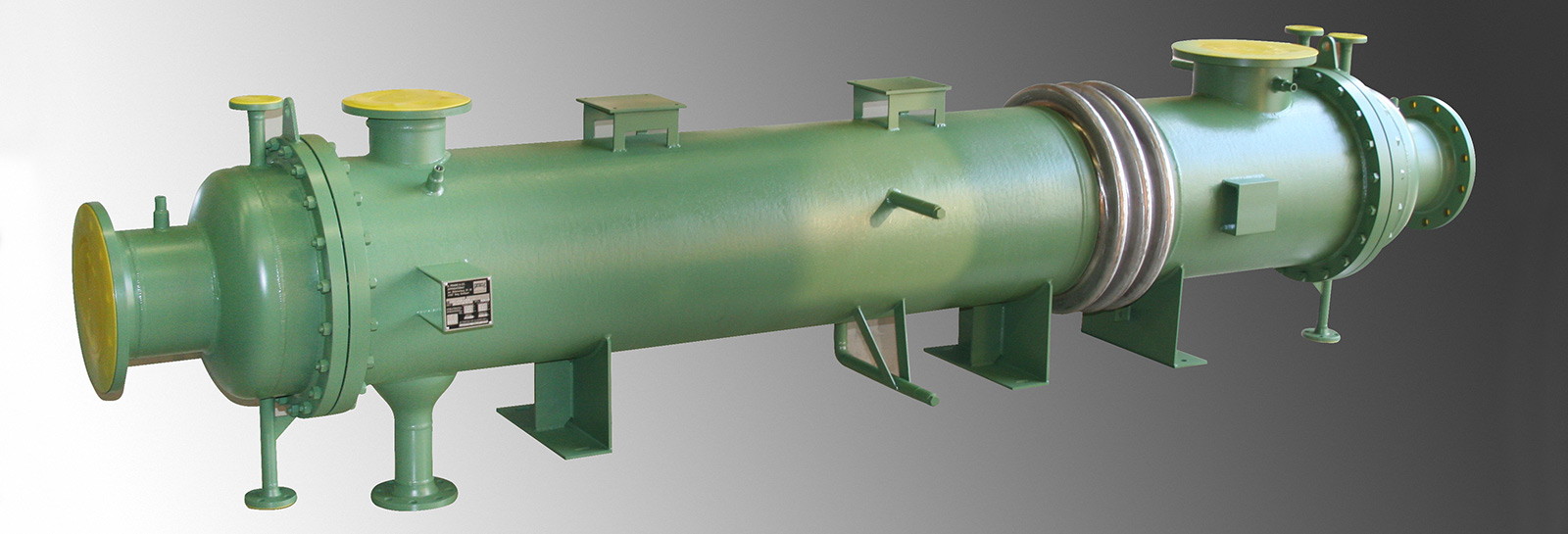

High-tech + craftsmanship = Maximum performance.

Individual solutions.

For over 70 years we have been specialising in the individual construction of heat exchangers - taking into account thermo-dynamic characteristics - complying with or even exceeding all manufacturing specifications. Every appliance is built with maximum competence and will provide benefits from which you will profit:

From development to production.

Functionally and economically.

Challenging operating conditions, in particular, will make our customised manufacturing process worth your while. From drive technology to cement plant design, the application possibilities of our heat exchangers are as varied as the thermal and production processes of the global industry.

Tailored to your area of application.

In consultation with you, our engineers and technicians tailor a heat exchanger - according to your technical demands, thereby securing the efficiency of your production processes and contributing to the success of your product and your production.

As manufacturers, we offer the complete package. From process layout and dimensioning of components over proposal preparations and production to the final acceptance inspection and document preparation – at E. Prang it's all under one roof.

Standard machines.

Since many decades we successfully manufacture standardised machines in small series for national and international located companies from the field of equipment and system-engineering. Due to these activities we have a construction kit of countless machines available, which we place also at your disposal.

If the right heat exchanger for your application cannot be derived from this kit, we gladly design a new model series exactly adapted to your repeating needs.

Frequently used medium:

- Oil - from edible oil to heavy fuel oil

- Water - from brackish water to demineralized water

- Gases - from biogas to carbon dioxide

- Steam - from oily steam to purest steam

- Substrata - from liquid manure to food waste

Typical construction materials:

- Steel

- High-grade steel / Special high-grade steel

- Titanium

- Copper

- Copper alloys

Depending on the task, we use different designs:

- Bare tube

- Ripped tube

- Safety double tube

- Straight tube

- U-tube

- One pass or multi-pass

- Vertical or horizontal